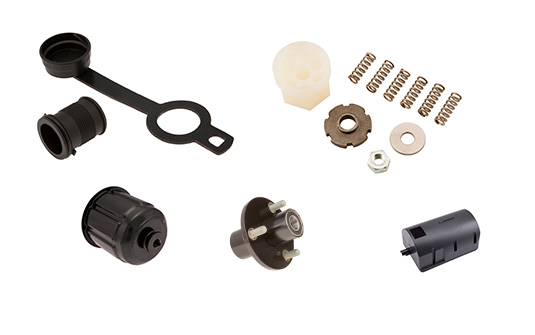

OEM Equipment Parts: Enhance Your Equipment with Genuine Equipment

OEM Equipment Parts: Enhance Your Equipment with Genuine Equipment

Blog Article

The Benefits and Drawbacks of Picking OEM Building Components Over New Parts for Your Devices

When it comes to maintaining and repairing tools, the decision between choosing for initial equipment supplier (OEM) construction parts versus new parts is a critical consideration for several businesses. While OEM components are created to satisfy the particular requirements of the equipment and are often connected with a higher degree of top quality and compatibility, there are likewise downsides to be evaluated, such as prospective expense effects and availability problems.

Top Quality and Compatibility Conveniences

When considering the top quality and compatibility advantages of OEM building and construction components versus repairs, it is vital to review their accuracy engineering and seamless integration abilities. OEM construction components, being original devices manufactured by the same business that created the devices itself, are designed to exact specs. This precision design guarantees that OEM parts are customized to fit flawlessly within the existing equipment, reducing the threat of malfunctions or compatibility problems. The compatibility advantages of OEM components prolong beyond simply fitment, as they are additionally crafted to function sympathetically with other components, maximizing the general efficiency and long life of the devices.

Higher Cost Factors To Consider

Provided the remarkable top quality and compatibility advantages of OEM building and construction components over new components, it is important to currently deal with the aspect of greater price considerations in the decision-making procedure. While OEM parts are recognized for their accurate fit and high efficiency, they frequently come with a higher rate factor contrasted to aftermarket alternatives. The first investment in OEM parts might seem more pricey, however over time, they can confirm to be more cost-effective as a result of their sturdiness and reliability.

When evaluating the higher price of OEM building and construction components is the possible cost savings in terms of minimized maintenance and repair work costs,One essential element to consider. OEM parts are engineered to meet the specific needs of the tools, which can lead to fewer breakdowns and much less downtime. This can equate into significant price financial savings for devices owners in regards to reduced repair work and replacement prices over the life-span of the equipment.

Furthermore, buying OEM components can likewise contribute to keeping the resale worth of the devices. Buyers frequently prefer equipment that has actually been fitted with real OEM parts, as they are perceived to supply much better quality and efficiency. This can lead to a greater resale value for the tools, balancing out the initial greater cost of OEM components. Ultimately, while the greater cost of OEM construction components may call for a larger upfront financial investment, the long-term advantages in regards to efficiency, reliability, and price cost savings make them a advantageous and feasible selection for equipment owners aiming to take full advantage of the worth of their investments.

Dependability and Service Warranty Protection

In assessing the option between OEM building parts and repairs, an essential facet to consider is the degree of reliability and guarantee insurance coverage offered. OEM building and construction parts, being made by the original tools maker, are created to meet the specific specifications of the devices, making certain a high level of dependability. These components undergo extensive screening to ensure compatibility and longevity, reducing the danger of breakdowns and breakdowns. In addition, OEM components frequently include a service warranty that offers coverage for a given duration, providing satisfaction to equipment owners in situation of unanticipated concerns.

On the other hand, brand-new components may not always use the very same level of dependability as OEM components, as they might not have been particularly created for the tools in question. When thinking about integrity and warranty protection, choosing for OEM building and construction components might supply a more protected and trustworthy service for devices maintenance and durability.

Efficiency and Long Life Enhancements

Having actually developed the significance of integrity and service warranty insurance coverage in the selection between OEM construction parts and new parts, the focus now shifts towards assessing exactly how these elements add to efficiency and durability improvements. OEM building components are engineered to exact specs, making sure smooth combination and optimum efficiency within the devices. This accuracy leads to enhanced general effectiveness and productivity, as the parts are developed to work harmoniously with the equipment they are intended for.

Additionally, OEM parts frequently undergo strenuous screening to satisfy industry standards and supplier demands, ensuring a greater degree of high quality compared to common options. This exceptional quality converts into increased resilience and longevity for the tools, decreasing the risk of unanticipated malfunctions and costly fixings. By using OEM construction components, equipment proprietors can experience enhanced efficiency, prolonged lifespan, and lessened downtime, ultimately causing enhanced functional efficiency and cost-effectiveness over time.

Prospective Limited Accessibility Issues

When depending on OEM building parts for devices upkeep and repair services, one significant drawback that can emerge is the possible restricted accessibility of these parts. As a my blog result of aspects such as production schedules, supply chain disruptions, or the discontinuation of particular elements by producers, there may be circumstances where OEM parts become limited and even obsolete. This deficiency can cause delays in equipment maintenance, prolonged downtime, and boosted prices connected with sourcing alternate options.

Restricted availability of OEM building and construction parts can additionally obstruct the efficiency of upkeep teams, as they might need to invest additional effort and time looking for ideal continue reading this replacements or waiting for back-ordered components to arrive. In situations where specific OEM components are essential for optimum devices efficiency or safety conformity, the unavailability of these elements can pose severe functional dangers. To minimize these challenges, devices supervisors ought to keep clear communication with vendors, explore choices for equipping crucial components beforehand, and think about different solutions or aftermarket parts when OEM alternatives are scarce.

Conclusion

Finally, when taking into consideration whether to choose OEM building components over repairs for equipment, it is necessary to consider the benefits of quality, compatibility, dependability, efficiency, and long life versus the drawbacks of higher expense and prospective minimal schedule. Ultimately, the decision ought to be based on the more information particular requirements and top priorities of the tools proprietor, as well as the importance of warranty protection in making sure long-lasting fulfillment and functional effectiveness.

When it comes to fixing and preserving devices, the choice between choosing for original equipment producer (OEM) building parts versus new parts is an essential consideration for many businesses.Given the superior top quality and compatibility advantages of OEM construction parts over new components, it is essential to currently address the facet of greater expense considerations in the decision-making process.On the various other hand, brand-new parts may not constantly use the exact same level of integrity as OEM components, as they may not have been specifically designed for the tools in inquiry.When depending on OEM construction components for devices maintenance and repairs, one substantial disadvantage that can arise is the possible restricted availability of these parts. To mitigate these obstacles, devices supervisors must maintain clear interaction with vendors, explore alternatives for stocking critical components in advancement, and consider alternate solutions or aftermarket components when OEM options are limited.

Report this page